Induction annealing

It is possible to locally heat workpieces with induction. For example, round and sealing seams to a diameter of more than 10 metres can be annealed or pre-heated at low stress with medium frequency induction annealing. Smit Heat Treatment has an extensive range of machinery, varying from 35KVA to 250KVA machines. Advantages of induction heating are the short pre-heating time and the extremely consistent temperature. High-frequency induction is also an option. This means that even extremely small, local repairs can undergo an effective heat treatment. Induction annealing can be used at any desired location. Moreover, it:

- is flexible in use.

- is a compact machine, which means low transport costs.

- executes exact temperature measurement by measuring the temperature of the workpiece.

- registers heat treatment on a 6 or 12-channel recorder.

Resistance heating

Smit Heat Treatment has 50KVA resistance machines with which we can execute heat treatments both at our branch sites as well as the location of your choice. Resistance heating is ideally suited to the heating of small to medium-sized round and sealing seams with diameters from 0.5 inches and for the execution of pre-heating work. Moreover, it:

- is flexible in use.

- is a compact machine, which means low transport costs.

- executes exact temperature measurement by measuring the temperature of the workpiece.

- registers heat treatment on a 6 or 12-channel recorder.

Stationary air atmosphere oven

Smit Heat Treatment has various ovens with different dimensions and properties that can be heated to a temperature of 1300 degrees. Smit also operates the longest air atmosphere oven in Europe. All our ovens meet all of the international standards stipulated by TÜV in AD Merkblatt HP 7/1 and SCIOS Scope 5.

Stationary inert gas atmosphere oven

An inert gas atmosphere oven is, in principle, the same as an air atmosphere oven, but then without an air atmosphere. Where a layer of oxides is deposited on the steel in an air atmosphere oven due to the reaction between metal and oxygen, this is not the case in an inert gas atmosphere oven. After all, the oxygen has been expelled and replaced with inert gas, which means that this reaction cannot take place and the steel remains untarnished. The great advantage of inert gas atmosphere ovens is that they are particularly well suited to products with extremely accurate dimensions. No subsequent treatments, such as blasting, are required because no rust needs to be removed.

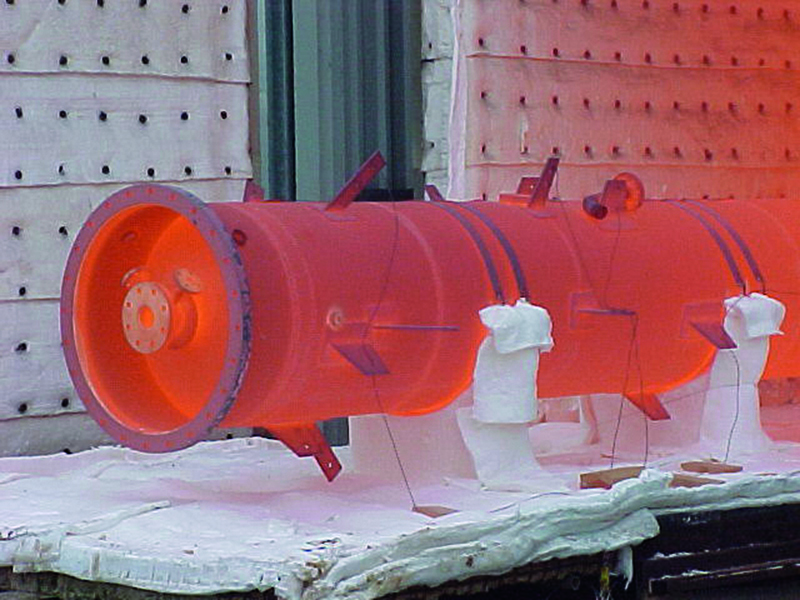

Mobile oven

A mobile oven is, in fact, the same as a stationary oven. However, the great advantage of a mobile oven, which is unique in the market, is that it can be installed at any location within a few days. Moreover, a mobile oven can be made as large or small as needed for the workpiece. Mobile ovens are actually built for a specific product that requires heat treatment and are completely harmonised to the specifications of that workpiece. In addition, we always strive to achieve optimum yield and low energy consumption.

Spot repair

Spot repair is high-frequency inductive annealing and is used on products with stable dimensions in particular. Spot repair annealing is intended primarily for the annealing of specific spots on certain products. This is because extreme heat can be applied in very small areas in just a few seconds. Spot repair is therefore a treatment that is executed very rapidly. This means that it is not necessary to wrap the entire device containing the specific part to be repaired.

People

Smit Heat Treatment employs a significant number of expert professionals who operate throughout Europe, and even beyond. Our experts possess a wealth of knowledge and experience in the field of heat treatment and are happy to actively contribute to your thought process. They ensure that your heat treatments are executed rapidly, efficiently and expertly.

Drying fireproof concrete

One of the annealing techniques used by Smit Heat Treatment is a High Velocity Burner. This is a burner with a high flame speed, and is used for the hardening of fireproof materials in particular.

Further information

If you would like more information on the annealing techniques used by Smit Heat Treatment, please contact us without obligation. We would be pleased to help you!