Extensive machine pool

Smit Heat Treatment commands an impressive machine pool with a wide variety of stationary furnaces in our facilities in Cuijk and Rotterdam, some of which were designed and developed in-house, allowing us to tackle any and all heat-treatment quandaries, no matter how complex or urgent. We have the perfect solution for every sector and every challenge.

Annealing furnaces

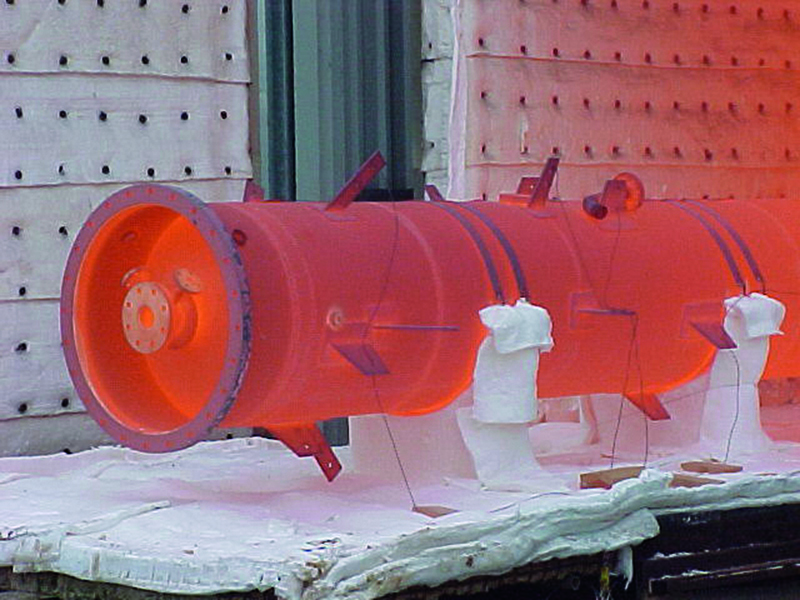

The Smit Heat Treatment machines include stationary gas-fired bogie-hearth furnaces and hood furnaces for large workpieces, and electric laboratory ovens for smaller orders.

The bogie-hearth furnaces enable us to simply roll the workpiece out of the oven using the built-in mobile floor. Hood furnaces entail a hood that is placed over the workpiece. These ovens are both perfect solutions for annealing processes that require extreme heating and swift cooling. Our on-site crane allows us to move workpieces weighing up to 70 tonnes.

Our annealing furnaces have widely varying dimensions, from a modest 600x600x600 millimetres to a whopping 22x5x5 metres, making Smit Heat Treatment the proud owner of Europe’s longest air atmosphere furnace. Besides air atmosphere furnaces, we also have a number of inert gas atmosphere furnaces, which are particularly suited for products with highly precise dimensioning. Our furnaces can reach temperatures of up to 1300 °C.